Artificial Intelligence in Logistics: Enhancing Every Component for Prosperity

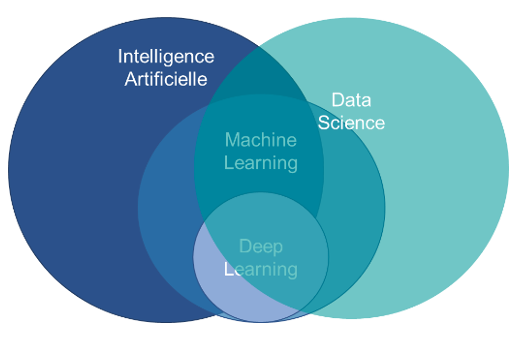

Within today's rapid corporate environment, organizations are incessantly looking for methods to achieve a market edge. One of the key disruptive innovations pushing this effort is artificial intelligence. Utilizing leveraging the power of AI, organizations can enhance their supply chain operations, improving efficiency and performance across each link. The implementation of AI not only streamlines workflows but also delivers key data that guide decision-making and cultivate creativity.

As businesses contend with the complexities of global logistics, the advantages of adopting AI grow increasingly evident. From analytical predictions that anticipate need to learning models that manage stock control, AI enables organizations to adapt swiftly to shifts in the business environment. This flexibility ensures that companies not only satisfy customer needs but also predict them, paving the way for long-term prosperity and viability in an constantly changing environment.

Boosting Product Forecasting

In the modern dynamic business landscape, precise demand forecasting is essential for prosperity. Legacy methods frequently depend on historical sales data and manual calculations, which can lead to errors and missed chances. The adoption of AI revolutionizes this process by examining vast volumes of data, such as market trends, consumer behavior, and external factors, to provide real-time insights. This transition allows organizations to make wise decisions and respond swiftly to changing market trends.

AI technologies can detect patterns and connections that human analysts might overlook. By leveraging machine learning, organizations can constantly improve their forecasting models based on recent data. This iterative improvement not only enhances accuracy but also reduces the risks associated with overstocking or stockouts. With increased reliable forecasts, businesses can streamline their inventory levels and cut holding costs, ultimately leading to enhanced operational efficiency.

Moreover, the use of AI in demand forecasting goes beyond internal data. By adding third-party factors such as economic indicators, social media sentiment, and competitor analysis, companies gain a comprehensive view of the market. This integrated approach provides companies with the tools to anticipate consumer needs and adapt their strategies proactively. The result is a supply chain that is not only nimble but also aligned with market demands, facilitating sustained growth and business advantage.

Improving Stock Management

AI technology transforms stock management by providing real-time data into stock levels, sales trends, and supply chain changes. With advanced algorithms, companies can anticipate stock requirements with more accuracy, reducing the risk of overstocking or running out of stock. This predictive capability allows companies to maintain appropriate inventory levels, ensuring that goods are readily accessible when consumers need them, while lowering excess and holding costs.

Moreover, AI can automate the replenishment process, facilitating the replenishment of stock. By evaluating sales data and consumer trends, AI systems can instantly trigger orders based on established thresholds. This not only frees time for supply chain managers but also increases the effectiveness of the supply chain. Elevated automation leads to greater responsiveness, enabling companies to react promptly to changes in customer needs and reduce lead times.

In addition, AI enhances coordination among different units involved in the logistics chain. With collaborative data analysis, teams can work together more effectively, exchanging information from marketing, promotion, and operations. This holistic approach fosters better judgments and synchronizes inventory management tactics with overall business objectives, ultimately driving advancement in a dynamic market.

Enhancing Logistics Processes

AI improves logistics operations by simplifying routine tasks, which allows businesses to handle their supply chain more effectively. Automated systems can manage inventory tracking, order processing, and route optimization, minimizing human error and liberating precious time for staff to dedicate time to strategic planning. This not only accelerates operations but also improves overall accuracy, resulting in better decision-making.

Moreover, using AI for predictive analytics enables companies to forecast demand in a more precise manner. By analyzing historical data and current market trends, AI can assist detect potential supply chain disruptions before they arise. This proactive approach allows businesses to adjust quickly and maintain continuity, ensuring that the right products are available at the right time.

Lastly, AI's ability to combine with other technologies enhances collaboration across the supply chain. With tools like machine learning and instantaneous data sharing, companies can synchronize their operations with suppliers and distributors. This integration leads to improved communication, lowered lead times, and ultimately, a robust logistics network, setting the stage for long-term success.